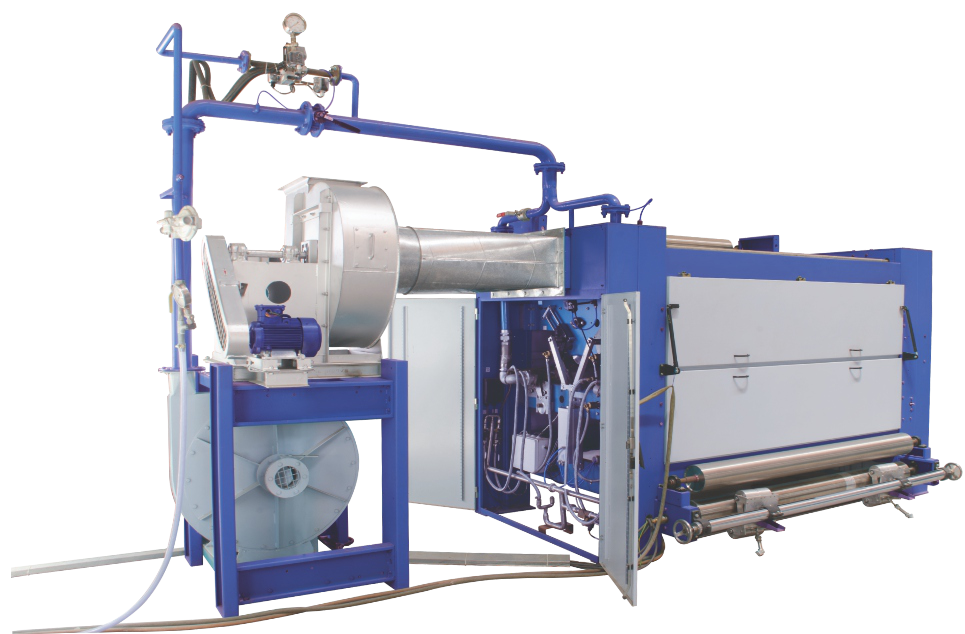

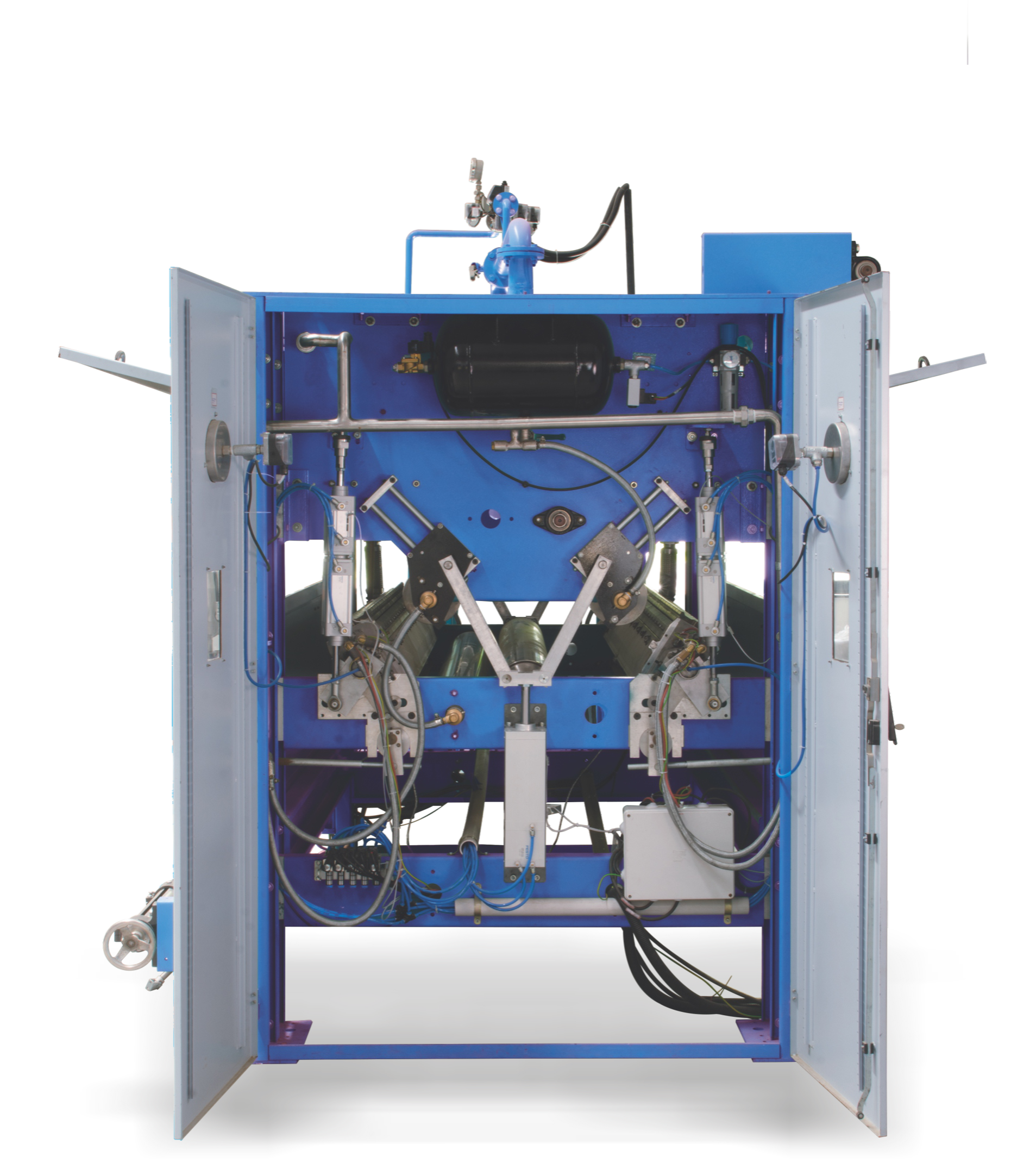

The 'Group Fourwents' Singeing Machines has been the global synonym of

top rate technology for best results in the finishing treatment of woven and knitted fabrics.The

Universal ‘Fourwents’ Singeing principle offers an individual adaptation to all the demanding finishing

effects along with versatile applications for the range

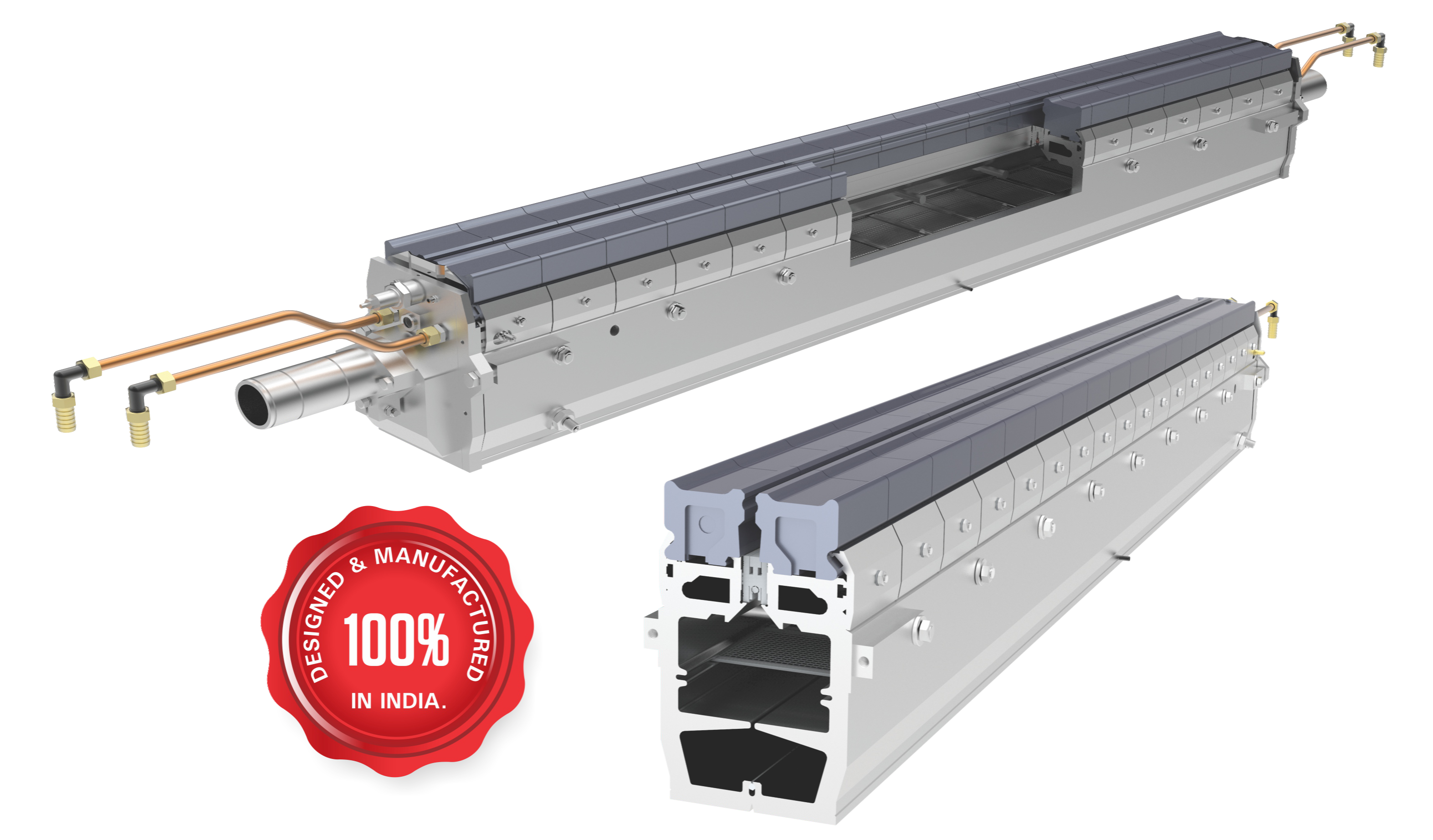

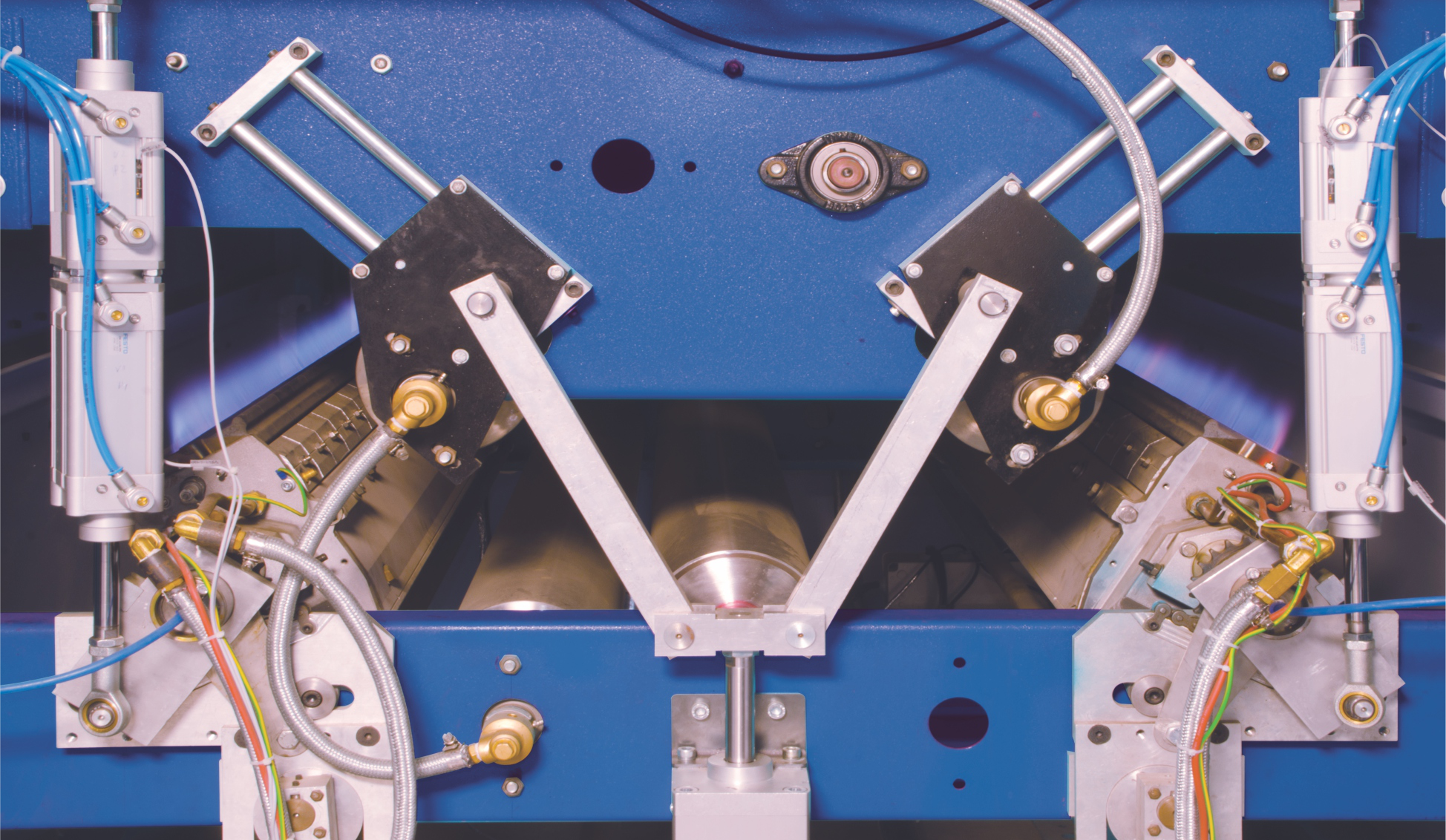

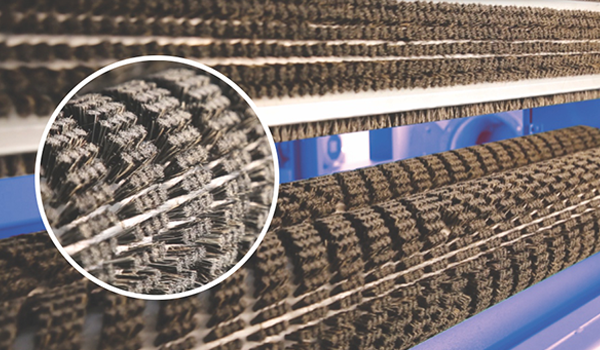

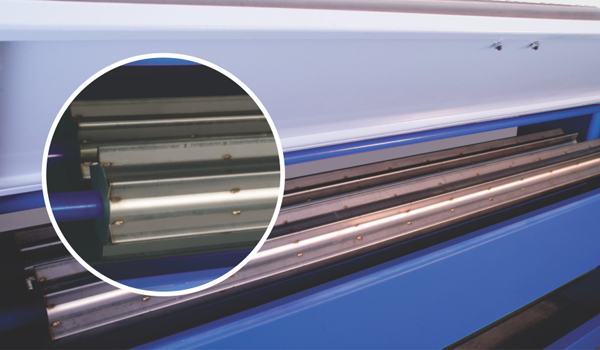

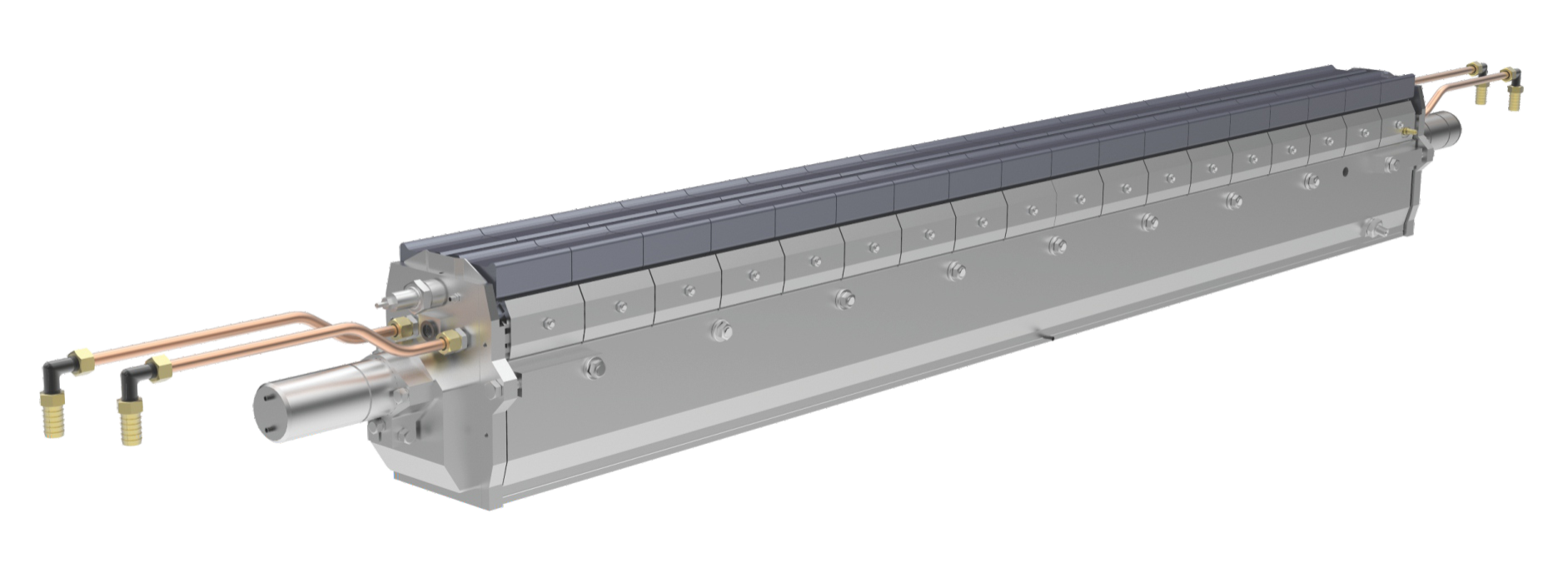

‘Group Fourwents’ designed the Dual-Jet Burner as well as regular Strip Type Burners are the heart of

the Singeing Machines.

‘Group Fourwents’ has designed high performance Dual-Jet Burners for all

machines in house. And that are successfully used world-wide, this allows

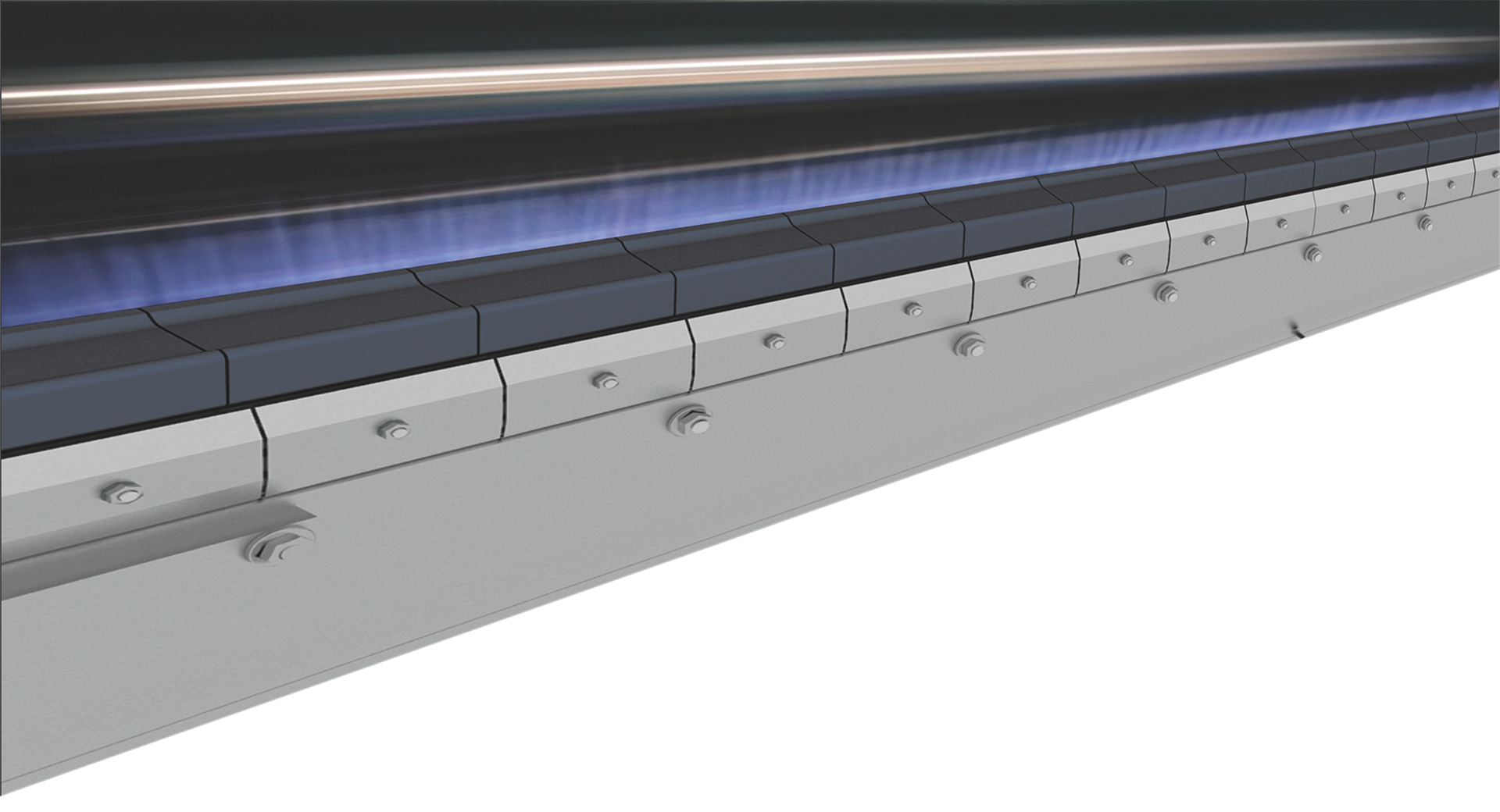

Fourwents to set high standards for the quality of the singeing flame generated in

the burner, which is the key function of the entire installation.

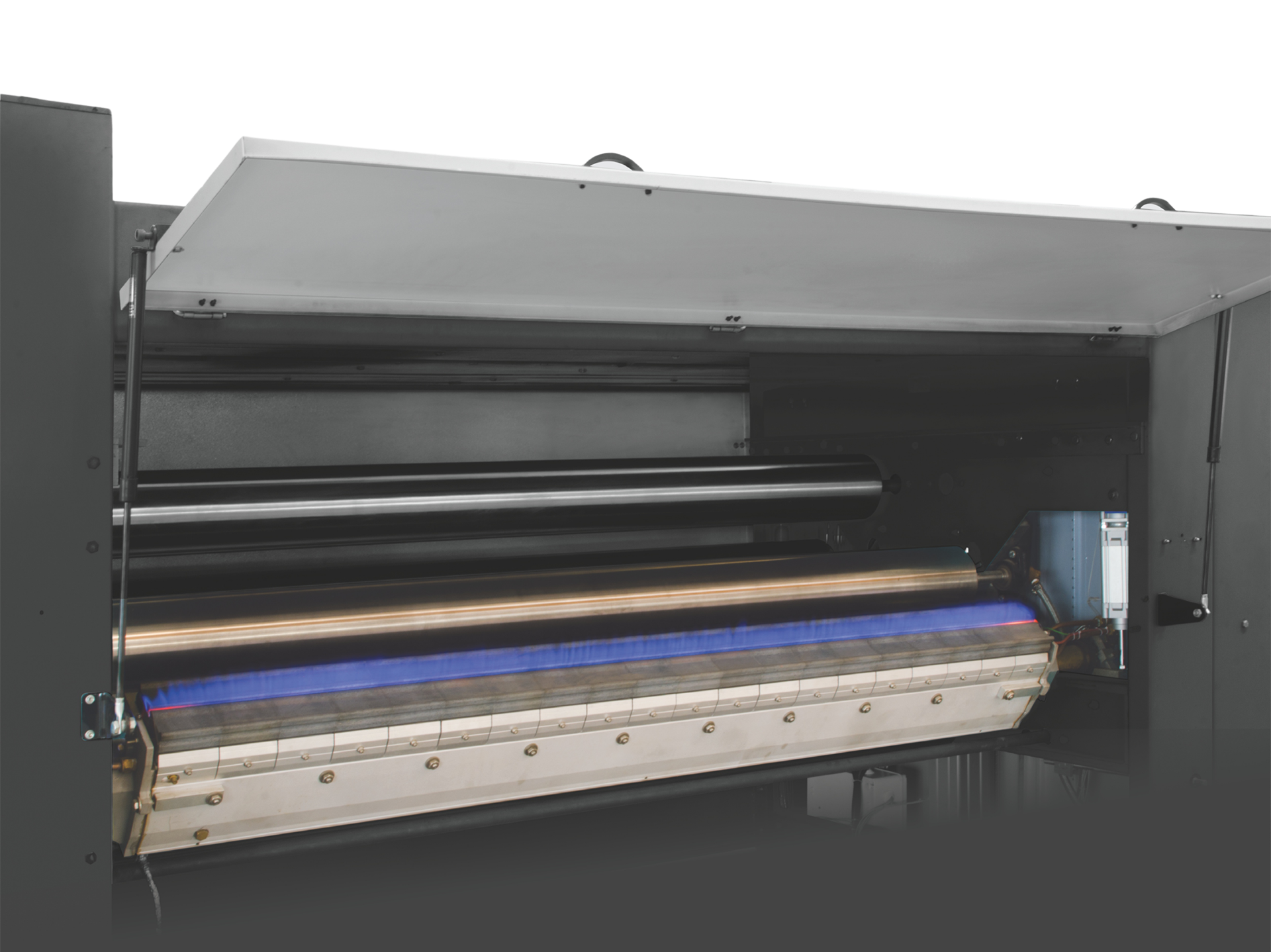

DUAL JET GAS SINGEING MACHINE

DUAL JET GAS SINGEING MACHINE

WIDER WIDTH 3200-3400mm

DUAL JET GAS SINGEING MACHINE

( MAINLY SUITABLE FOR BED SHEETS & CURTAIN FABRICS )

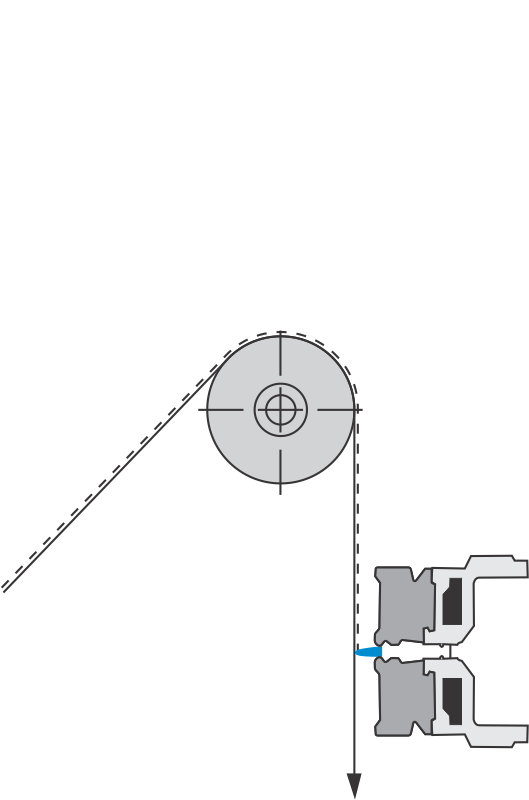

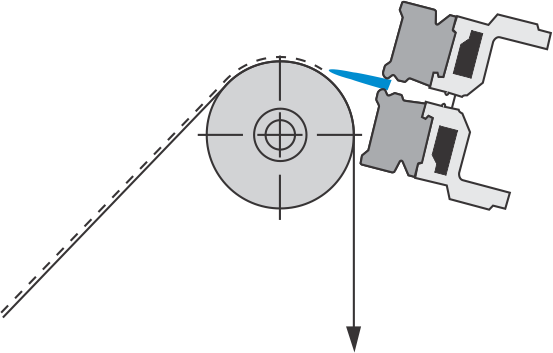

SINGEING ONTO

FREE-GUIDED FABRIC

THE SINGEING FlAME MEETS THE FREE-GUIDED AT RIGHT ANGLES AS THE FABRIC PASSES BETWEEN TWO GUIDE ROLLERS. THE POSITION IS RECOMMENDED FOR MATERIALS MADE OF 100% NATURAL FIBERS AND FOR BLENDED FABRICS WHICH HAVE BEEN THOROUGHLY BEATEN, WITH WEIGHTS OVER 125 G/M².

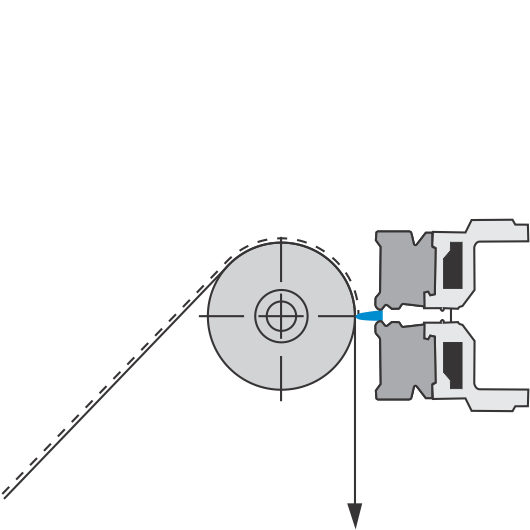

SINGEING ONTO

A COOLED ROLLER

THE SINGEING FLAME MEETS THE FREE-GUIDED AT RIGHT ANGLES AS IT IS BENT OVER A WATER COOLED ROLLER.

THE CHOICE OF THIS POSITION IS RECOMMENDED FOR QUALITIES OF FABRIC COMPOSED OF TEMPERATURE SENSITIVE FIBERS, OPEN-WEAVE BLENDED FABRICS AND THOSE WITH WEIGHTS OF LESS THAN 125G/M².

TANGENTIAL

SINGEING

THE SINGEING FLAME PASSES CLOSE TO THE FABRIC WITH THE JET DIRECTION BEING AT A TANGENT TO THE FABRIC SURFACE. THIS SINGING PROCESS IS RECOMMENDED FOR ALL MATERIALS WHICH CANNOT TOLERATE DIRECT EXPOSURE TO FLAME. TANGENTIAL SINGING CAN ALSO EQUALISE PROTRUDING FIBERS AND REPAIR FILAMENT BREAKS.

IN ADDITION TO THE SINGING POSITION THE SINGING EFFECT CAN ALSO BE INFLUENCED BY VARIATION OF KEY SINGING PARAMETERS NAMELY SPEED, FLAME INTENSITY AND DISTANCE OF FABRIC FROM THE BURNER. THESE ARE READILY ADJUSTED AND MONITORED MAKING THE PROCESS MORE PRECISE AND REPRODUCIBLE

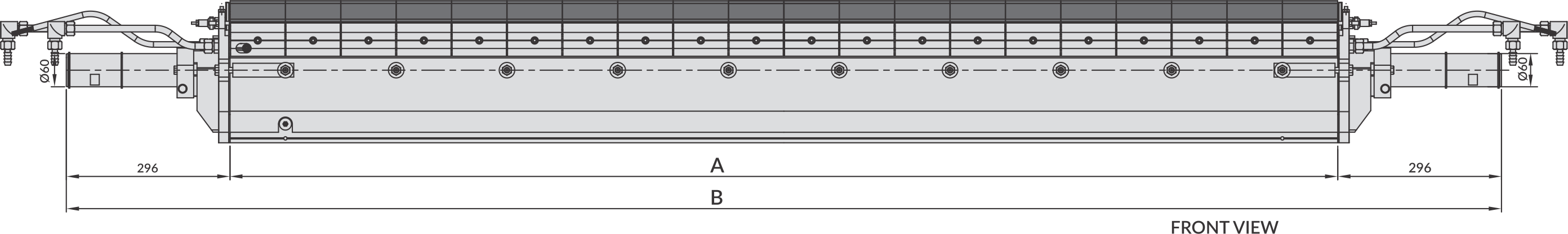

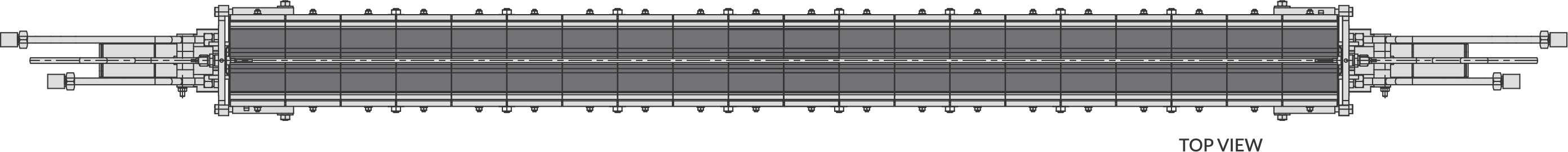

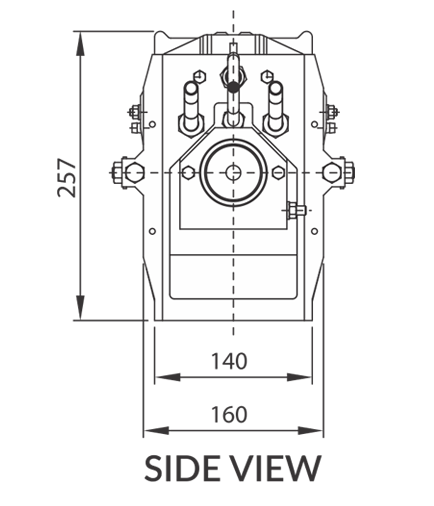

| BURNER WIDTH | W/W | A | B |

|---|---|---|---|

| 1800 mm | 1600 mm | 1800 | 2392 |

| 2000 mm | 1800 mm | 2000 | 2592 |

| 2200 mm | 2000 mm | 2200 | 2792 |

| 2400 mm | 2200 mm | 2400 | 2992 |

| 2600 mm | 2400 mm | 2600 | 3192 |

| 2800 mm | 2600 mm | 2800 | 3392 |

| 3000 mm | 2800 mm | 3000 | 3592 |

| 3200 mm | 3000 mm | 3200 | 3792 |

| 3400 mm | 3200 mm | 3400 | 3992 |

| 3600 mm | 3400 mm | 3600 | 4192 |

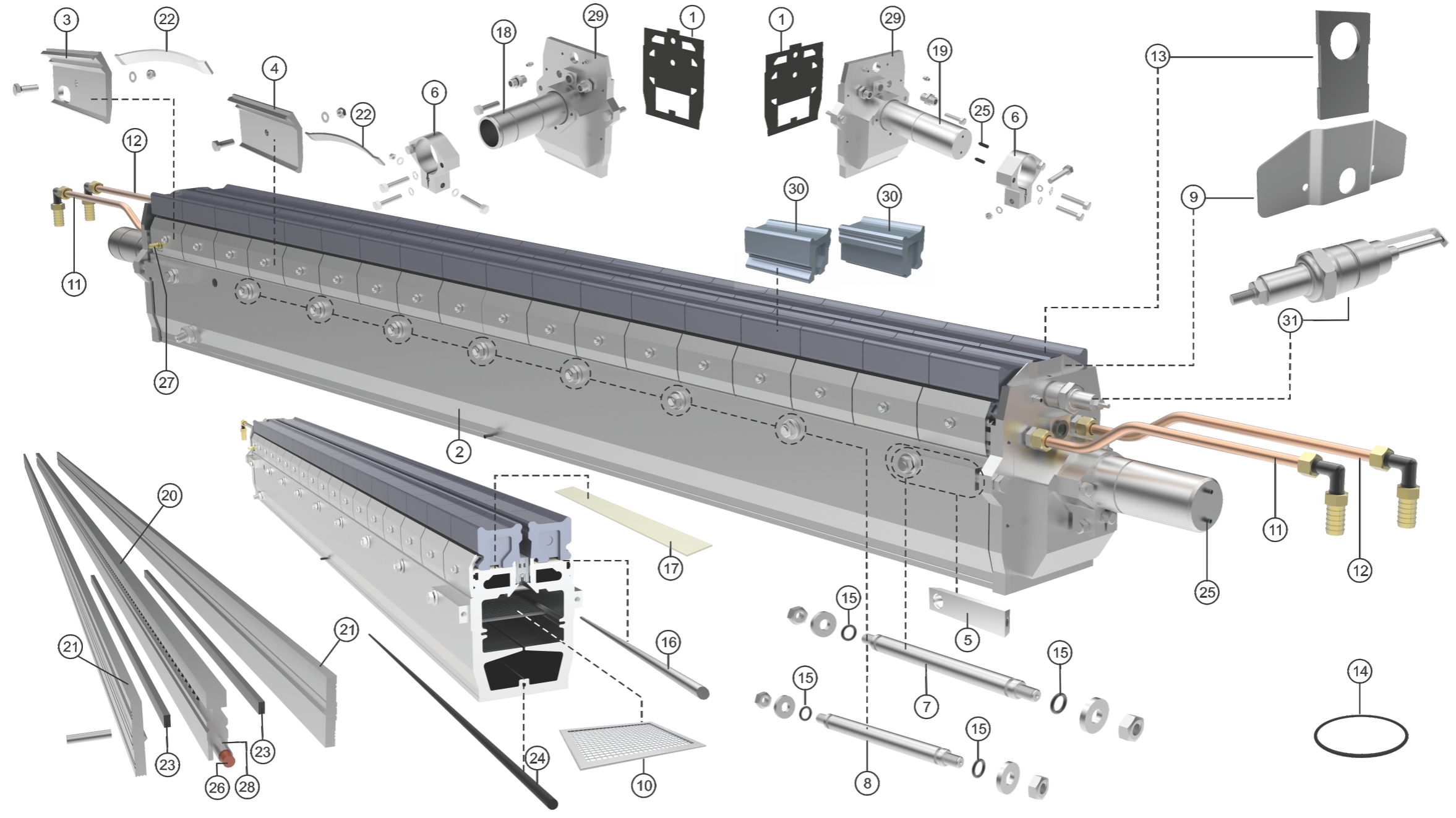

| POS. NO. | DESCRIPTION OF ITEMS | QUANTITY |

|---|---|---|

| 1 | FLANGE GASKET | 2 |

| 2 | BURNER BODY | 2 |

| 3 | CLAMP PLATE (WITH SLOT) | 2 |

| 4 | CLAMP PLATE (WITHOUT SLOT) | 34 |

| 5 | SUPPORT (25x15x110) | 4 |

| 6 | FIXING FLANGE | 2 |

| 7 | THREADED BOLT SHORT | 7 |

| 8 | THREADED BOLT LONG | 2 |

| 9 | FLAME SHIELDING PLATE | 2 |

| 10 | FLAT FILTER | 18 |

| 11 | INLET PIPE SMALL | 2 |

| 12 | INLET PIPE LONG | 2 |

| 13 | SEALING SET | 2 |

| 14 | CFT 'O' RING | 2 |

| 15 | O' RING (I.D.11 x Ø2.5) | 18 |

| 16 | ROUND ROD (Ø3x200) | 18 |

| 17 | SUPERWOOL ISOLATION STRIP (39x2x400) | - |

| 18 | SHAFT END - 1 | 1 |

| 19 | SHAFT END - 2 | 1 |

| 20 | BURNER MIDDLE RAIL (33.5x10x1796) | 1 |

| 21 | BURNER SIDE RAIL (36x7x1796) | 2 |

| 22 | SPRING STEEL STRIP | 18 |

| 23 | GASKET (3x6x285) | 2 |

| 24 | RUBBER CORD (Ø6x1800) | 1 |

| 25 | GRUB SCREW (M8x25) | 2 |

| 26 | SILICON RUBBER CORD FOR GAS SPRING | 1 |

| 27 | VENT SCREW - 1/8" | 1 |

| 28 | SPRING L-285 | 1 |

| 29 | BURNER FLANGE | 2 |

| 30 | BRICKS | 36 |

| 31 | SPARK PLUG | 1 |

Made in india